Expanders

Modules Applications

Expanders

Modules Applications

Integral gear based turbo-expander provides numerous advantages over traditional single shaft turbines. It acts as an enabler for numerous classical or innovative solutions

See architecture

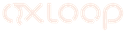

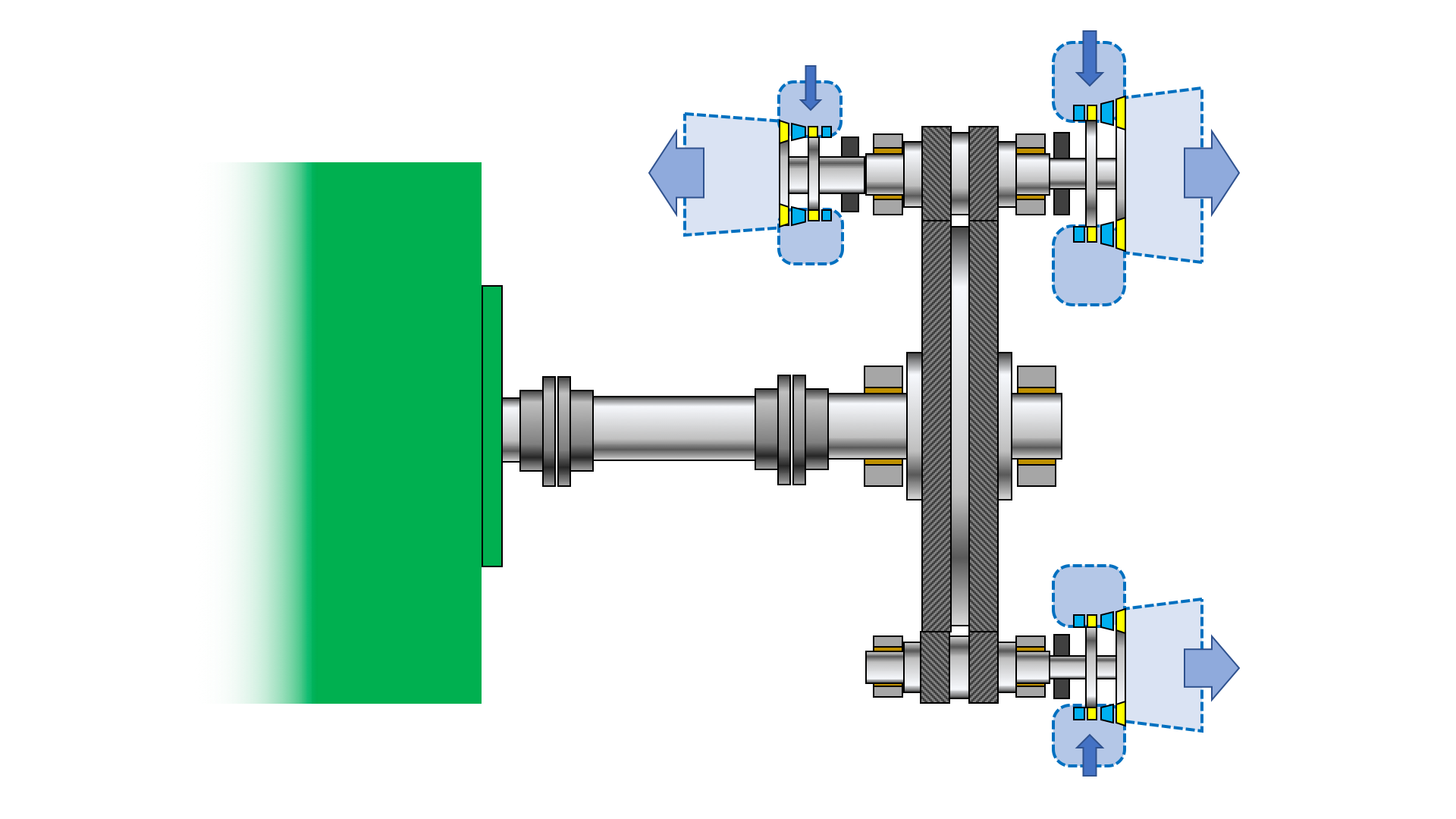

Multiple turbine bodies enables a large combination of arrangements.

Integral gear based turbo-expander provides numerous advantages over traditional single shaft turbines. It acts as an enabler for numerous classical or innovative solutions

See architectureLeverage inexpensive saturated steam generators in high efficiency power cycle by suppressing moisture-related blades erosion in turbine last stages.

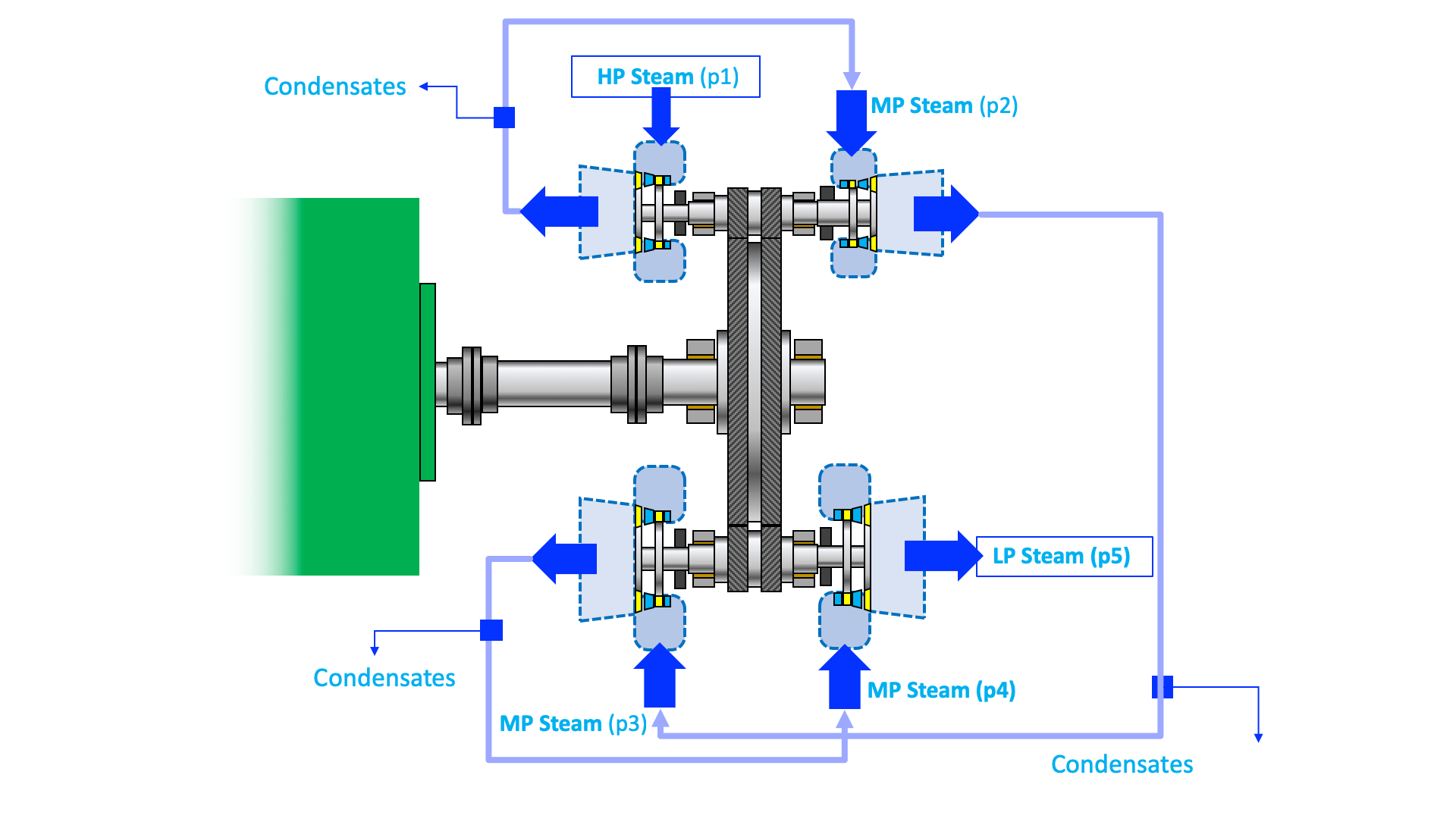

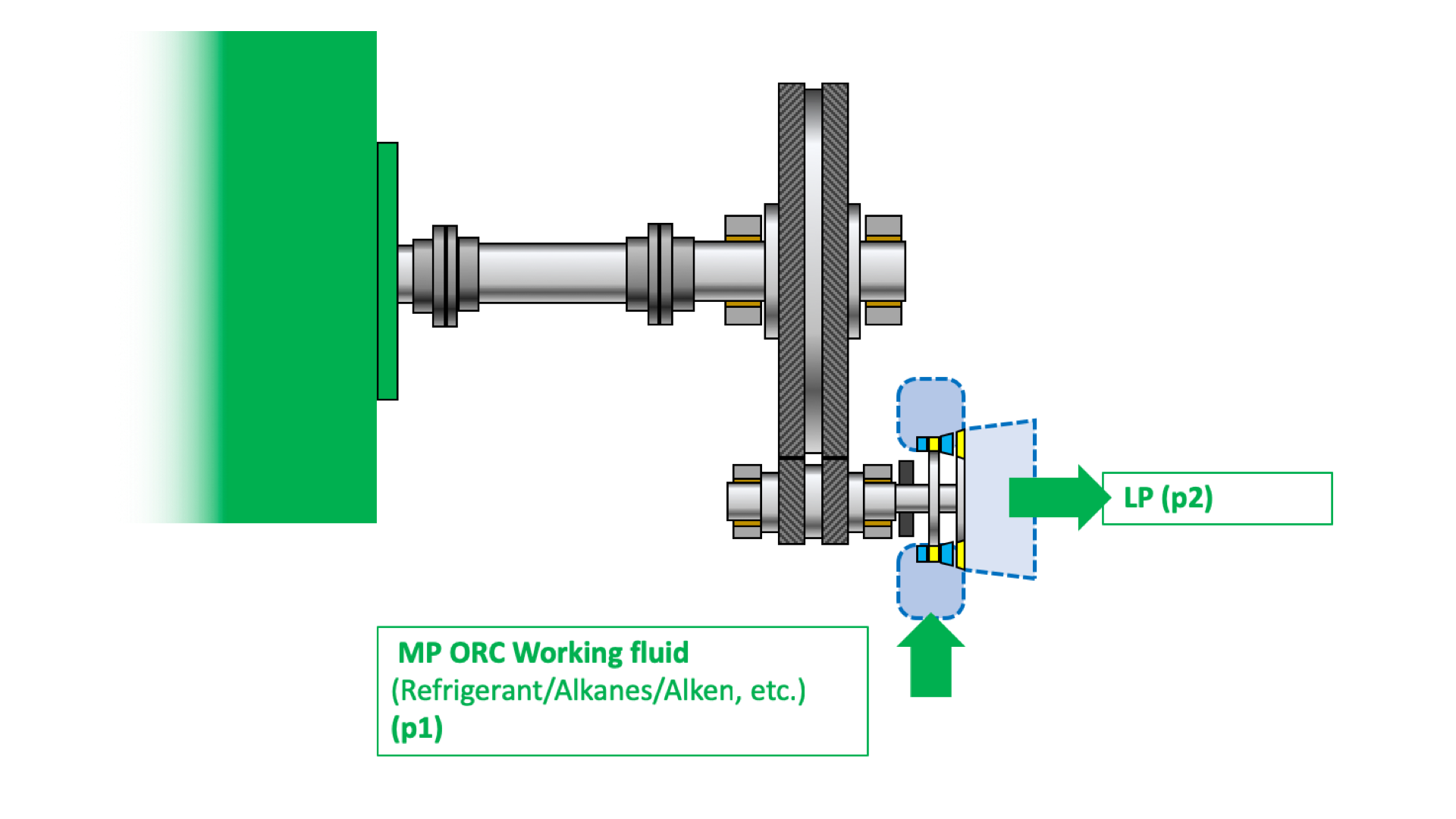

Overhung cantilevered single shaft architecture for simple, for an easily maintenable yet highly efficient expander. From 250 kW up to 2 MW. Perfect for low volume flow and low to medium enthalpy drop. Ideally suited for refrigerant such as R1233zd, R1234ye, pentane, butane.

Overhung cantilevered single shaft architecture for an engineered and highly efficient expander. From 250 kW up to 5 MW. Adapted for high volume flow and medium to high enthalpy drop. Ideally suited for refrigerant such as pentane, butane, toluene, hexamethyldisiloxane, octomethyltrisiloxane.

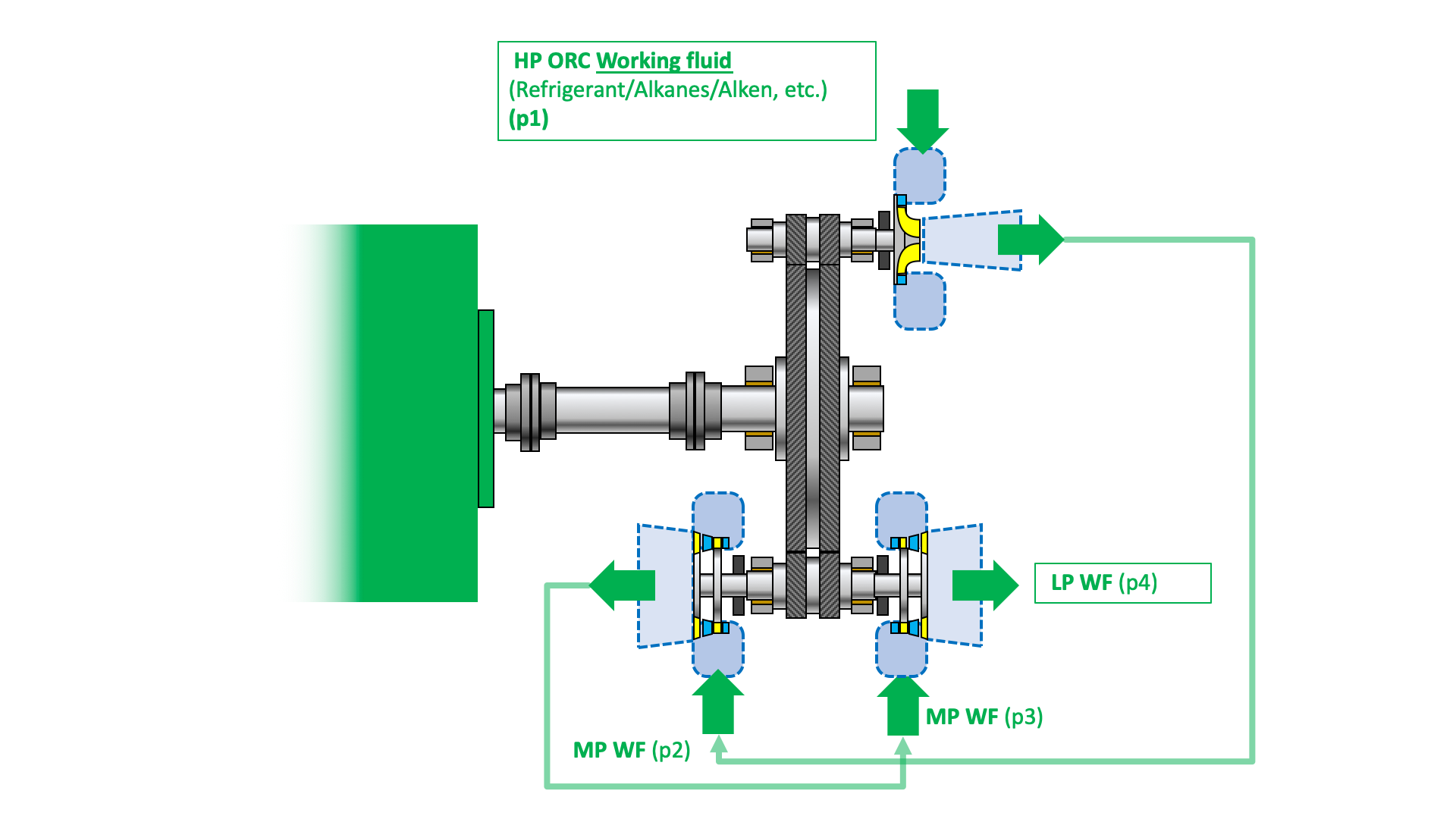

Adapted for high volume flow and high enthalpy drop for the utmost performance. Ideally suited for refrigerant such as pentane, butane, toluene, hexamethyldisiloxane, octomethyltrisiloxane. Power up to 8MW.

Up to 4 turbines for the maximum expansion ratio. Use high speed shaft for HP->MP expansion, low speed shaft for MP->LP expansion (allowing turbines rotational speed to be the most appropriate).

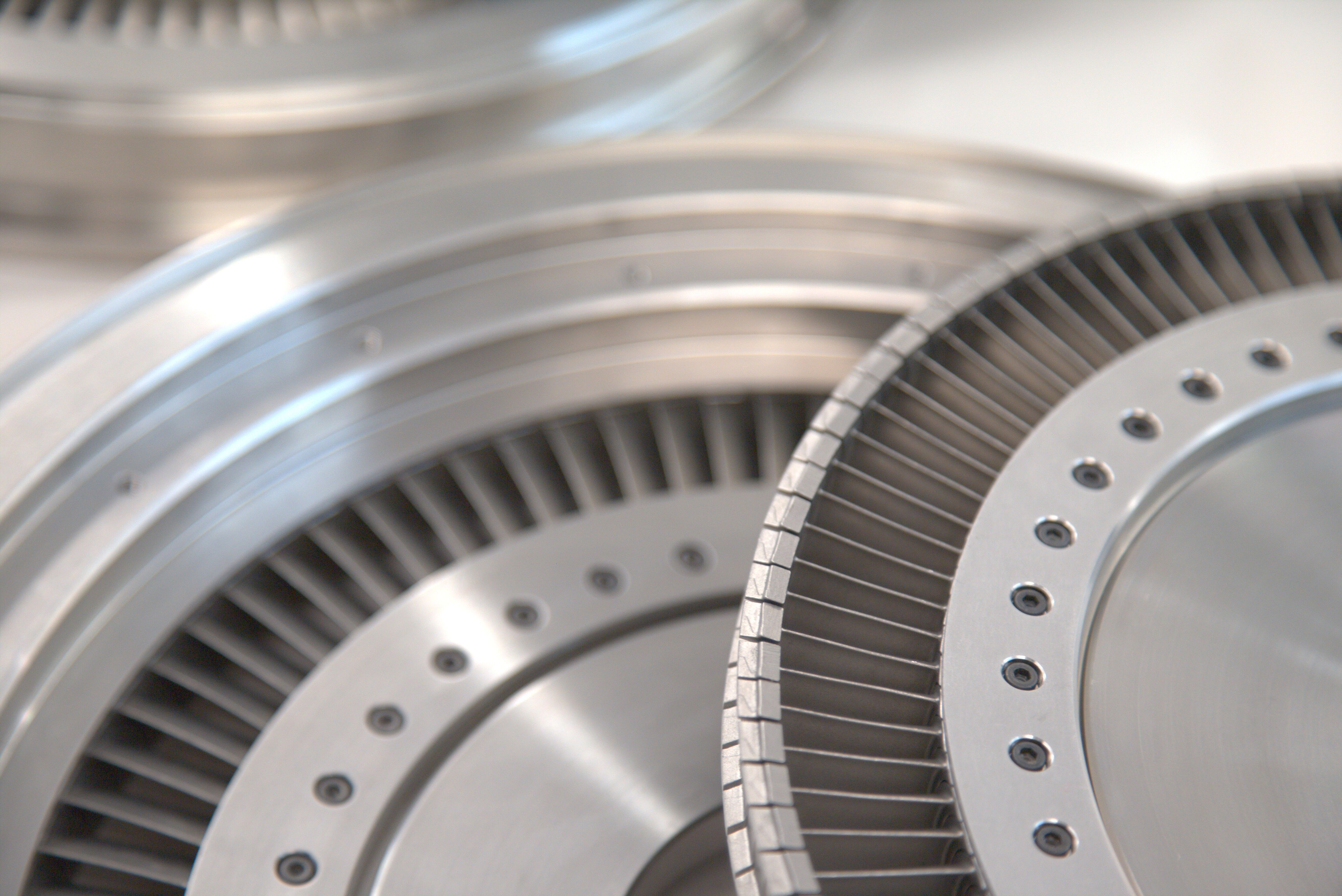

We provide radial and axial designs to cover for a wide range of industrial and utility needs.

See architecture

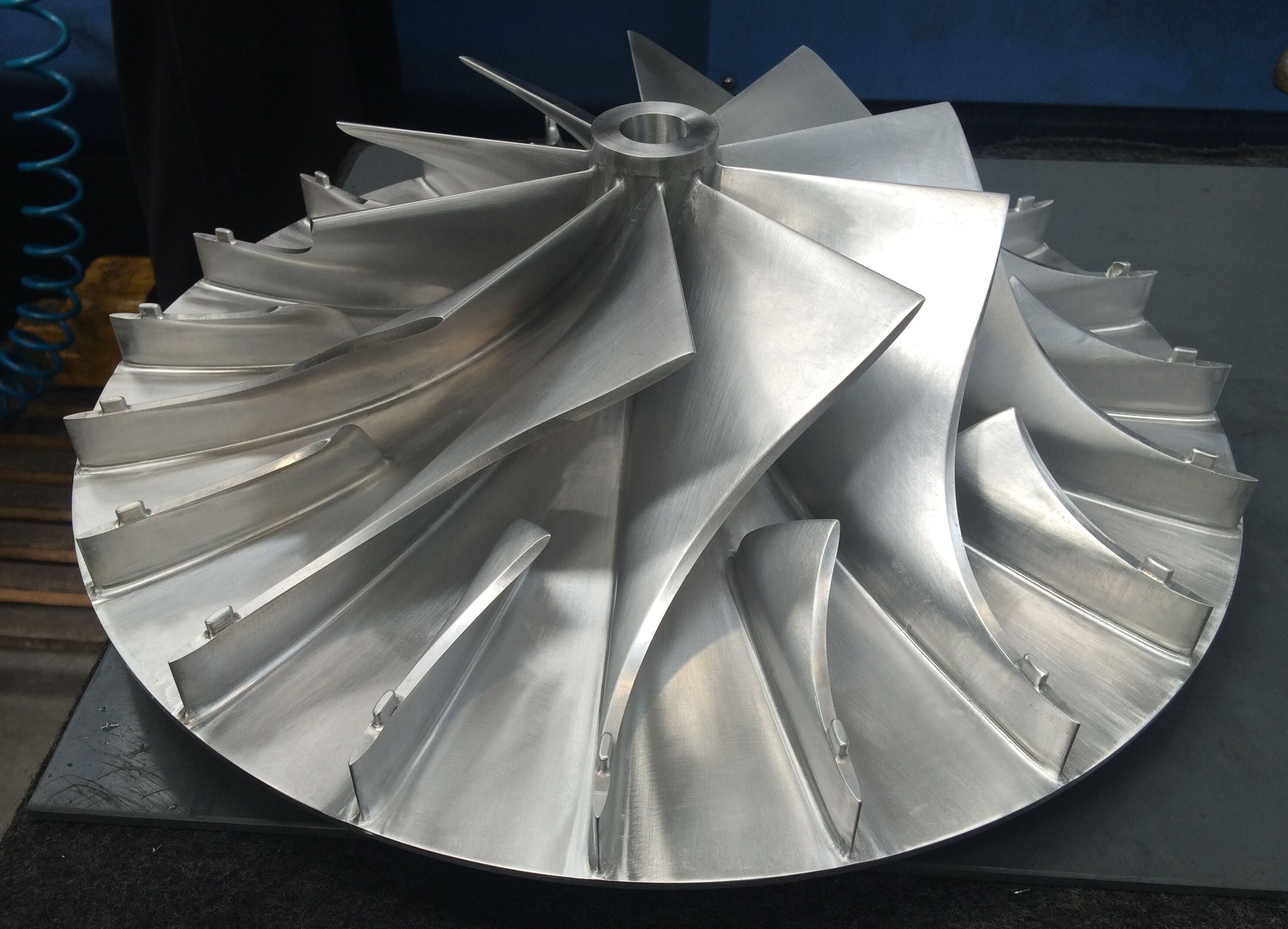

Machined directly from our design with CNC - 5 axis, radial turbines can easily be customized for a wide range of applications. They offer numerous advantages:

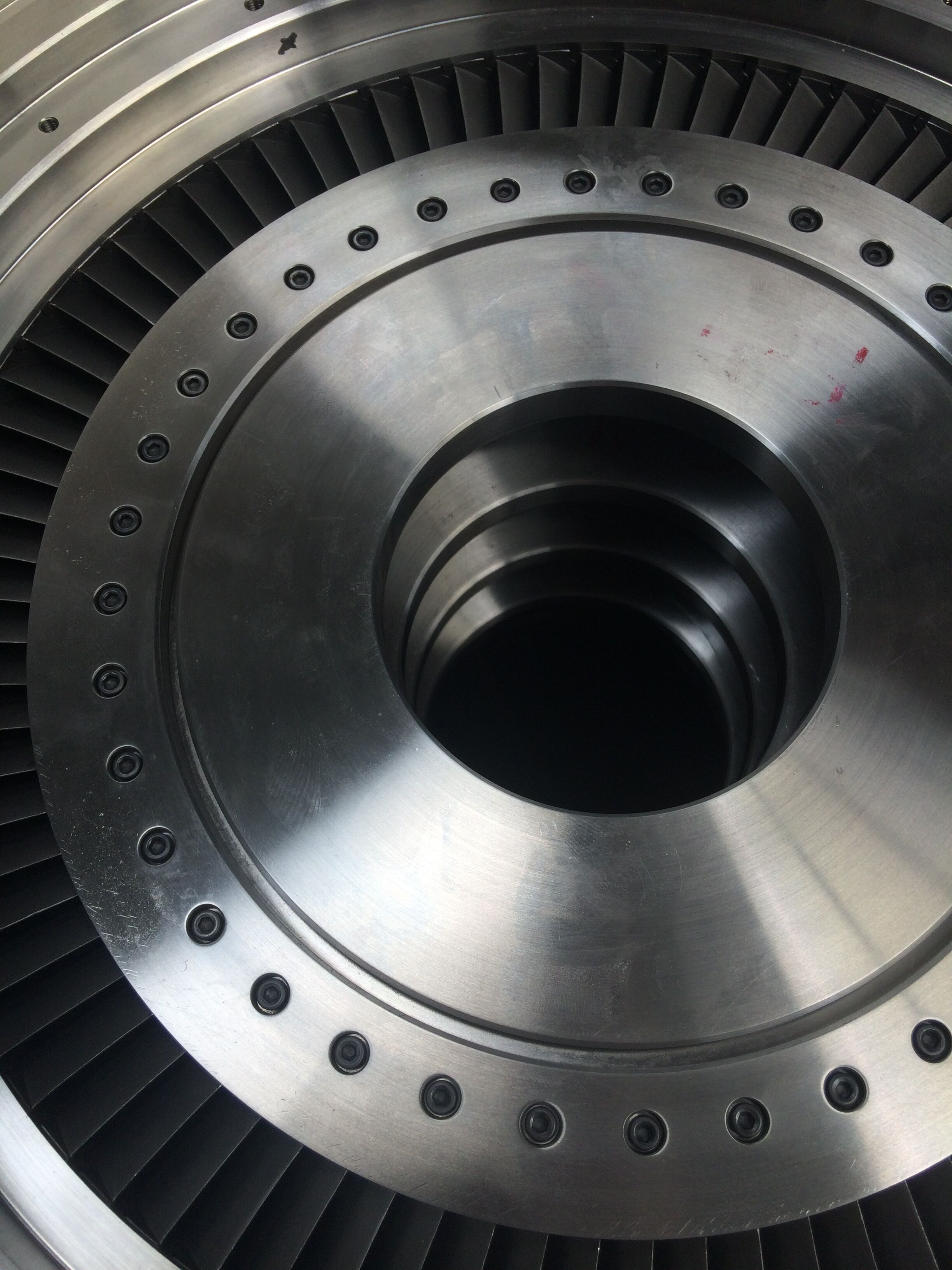

Blades and machined directly from our design with CNC - 5 axis. They offer numerous advantages:

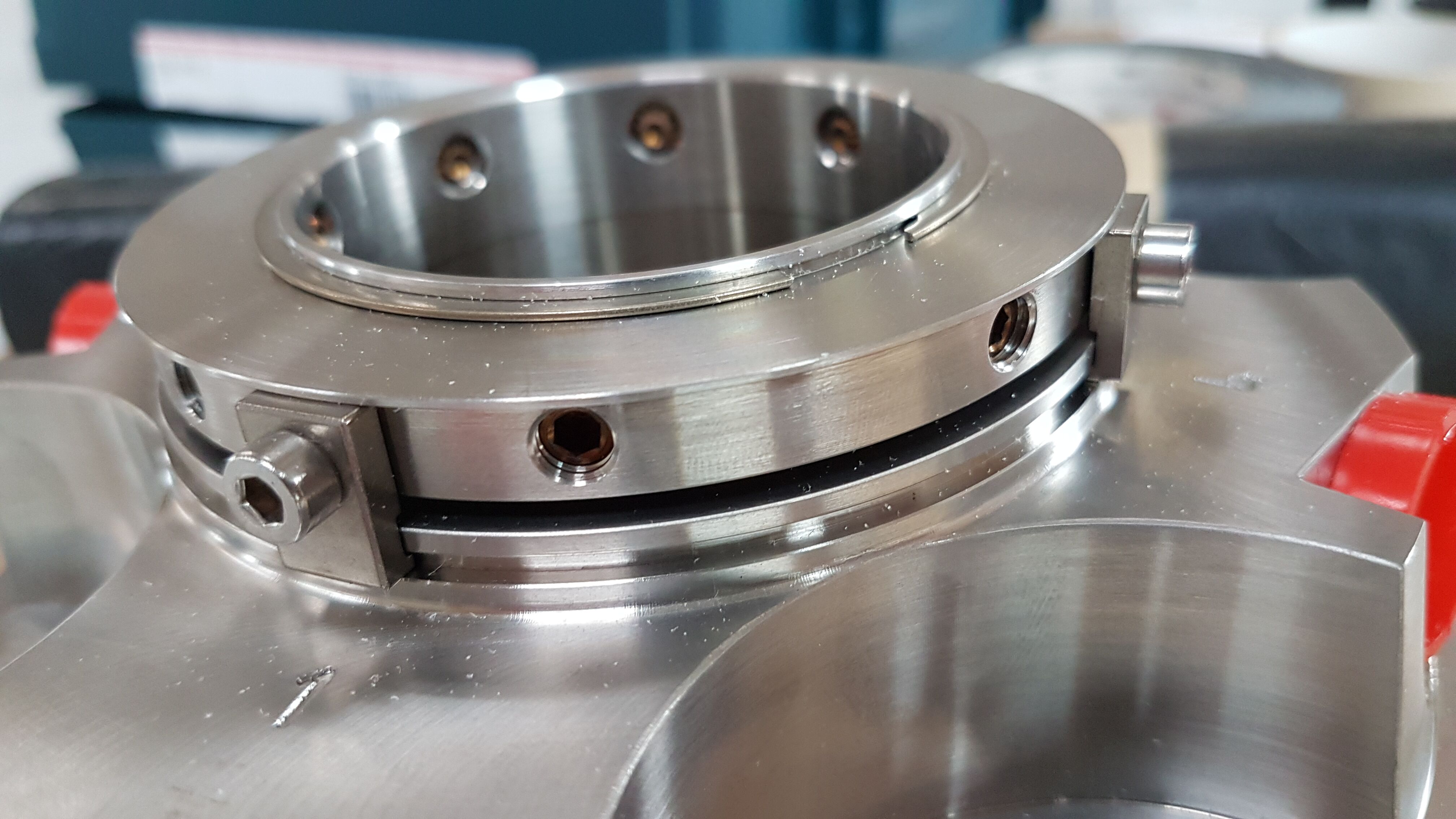

Our carefully selected partners provide for the more robust and energy efficient shaft sealings.

See architecture

Reference solution for organic fluids since barrier oil can be extracted from the process continuously.

Reference solution for steam, sinc it allows super high sliding velocity.

Left picture: Courtesy of Eagle-Burgmann.

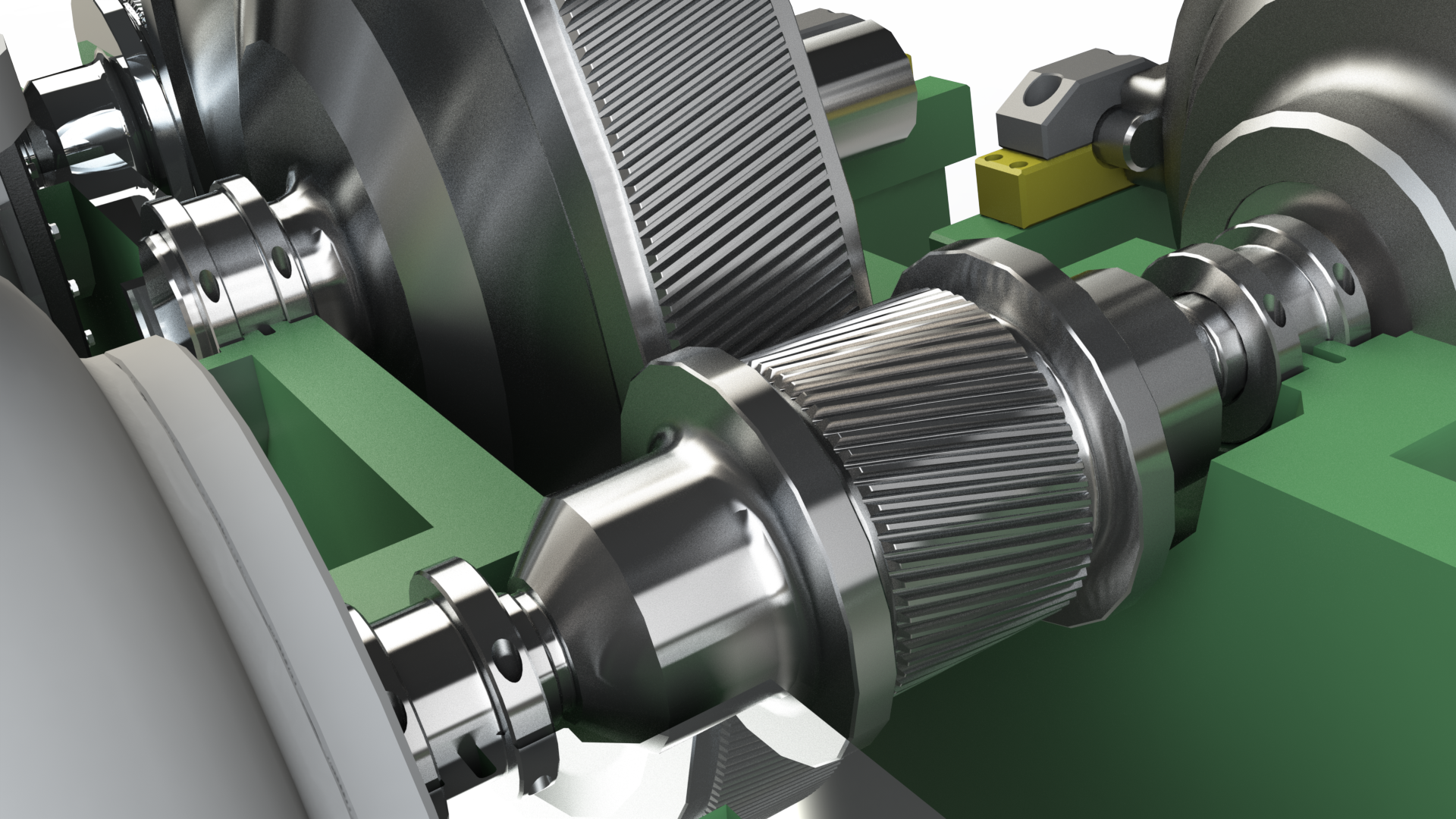

That's why we collaborate with experienced manufacturers such as Voith, Renk or Flender-Graff

See architecture

Integral gear design and manufacturing gathers lubrication, roto-dynamics and so on, leaving QxLoop team focused on turbine rotational speed definition.

We have setup a wide network of partners able to tackle all manufacturing aspects.

Contact us at: contact@qxloop.com

Careers: applications must be made at: contact@qxloop.com

QxLoop is a registered trademark of Ubiplant SAS.

Copyright © 2019 Ubiplant SAS. All rights reserved.

All images, names and trademarks protected.