Expanders Modules Applications

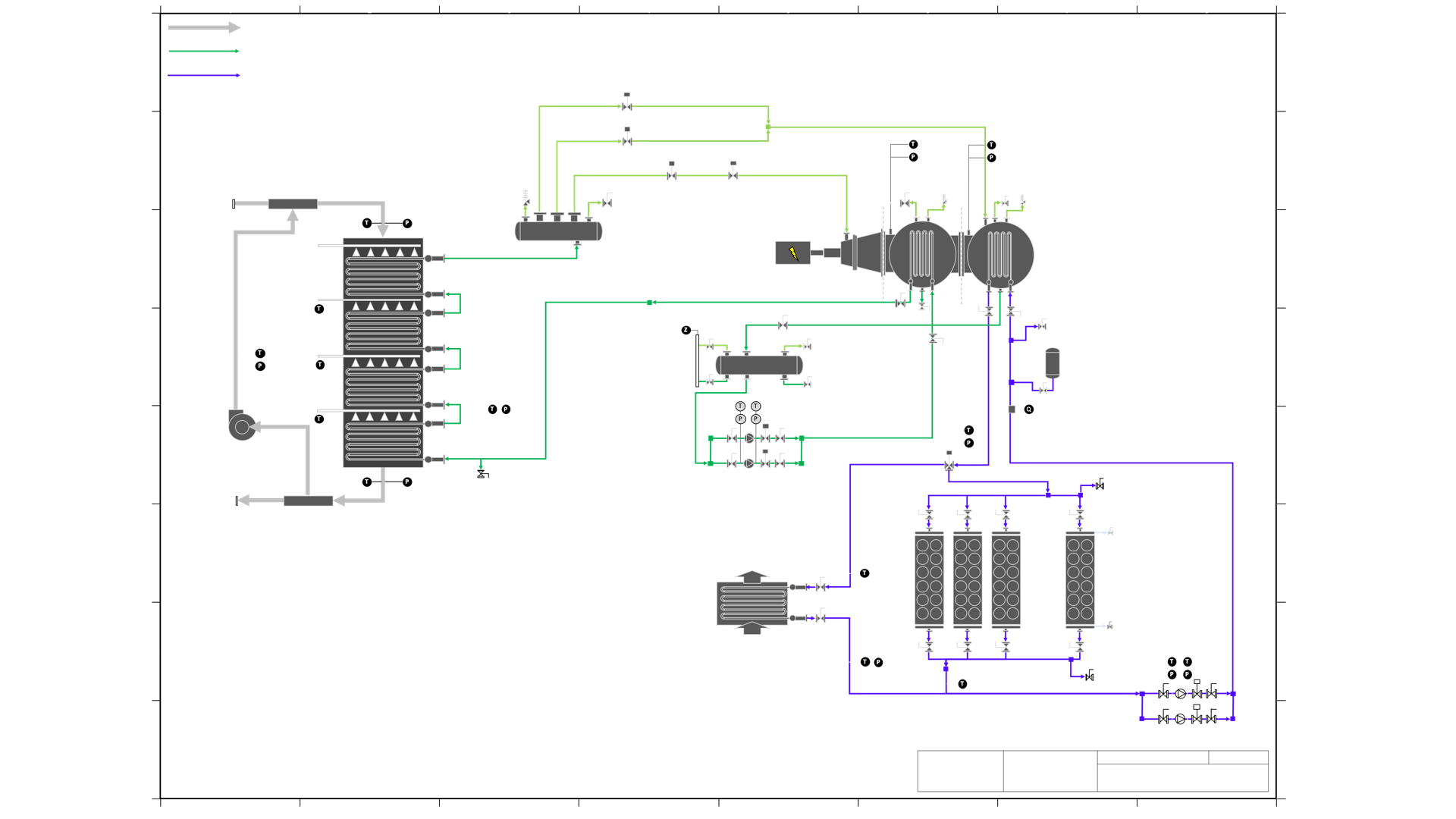

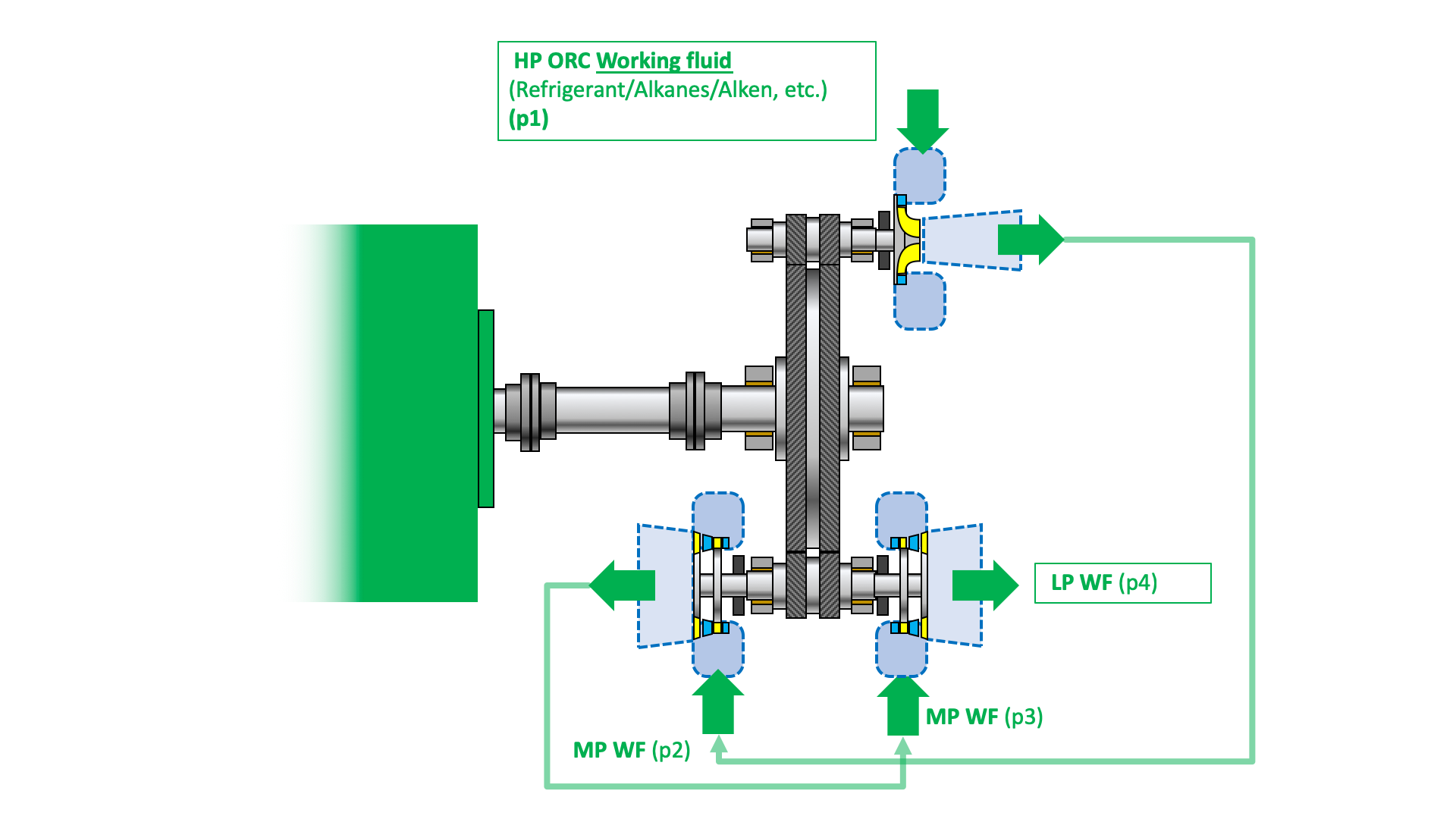

Expanders Modules Applications UA2-UA2[Tl]-G:350/180-W:50/30-4000 is a pre-engineered module(meaning that it requires minimal tuning before it can be put in production).

It uses a Simplified Organic Rankine Cycle based on UA2 ORC module architecture with a direct evaporation. Toluene is used both as Heat transfer fluid and Working fluid, allows to:

Integrated evaporator is replacing the exchanger of the boiler, so only requires furnace and flue gas treatment to complete power generation unit.

Well-suited for municipal-sized incinerators with high performances.

Industrial Waste Heat Recovery on flue gases is made simple since UA2-DE saves the thermal oil loop and widen pinches by removing the intermediate loop. Larger pinches means smaller evaporator size, resulting in additional cost savings.

Many heavy fuel or diesel engines are lacking a proper WHR solution. UA2 can easily turned a simple cycle in combined cycle.

Gas turbines are known for their ease of operation, especially compared to engines. But they are lacking performance compared to reciprocating engines. Turning them in combined cycle is simple way to close the gap while still benefiting from turbines easier O&M.

| Parameters | Value | Unit |

| Nature | Flue gas | |

| Thermal power | 16 936 | kWth |

| Inlet temperature | 350 | °C |

| Outlet temperature | 180 | °C |

| Volume flow | 241 367 | N m3/h |

| Parameters | Value | Unit |

| Working fluid | Toluene | |

| Gross power | 4 000 | kWelec |

| Gross Efficiency | 23.60% | |

| Net power (including module pumps and auxiliaries, excluding cooling) | 3 739 | kWelec |

| Net Efficiency | 22.10% | |

| Parameters | Value | Unit |

| Cooling fluid | Water | |

| Dissipated thermal power | 12 562 | kWth |

| Inlet temperature | 25 | °C |

| Outlet temperature | 45 | °C |

| Volume flow | 543 | m3/h |

See our expanders here

Evaporator can be supplied by various manufacturers among our partners. One of the most experienced is Geurts who already owns a long track record.

Contact us at: contact@qxloop.com

Careers: applications must be made at: contact@qxloop.com

QxLoop SAS.

Copyright © 2019 QxLoop SAS. All rights reserved.

All images, names and trademarks protected.